Sustainable Concrete Initiative

The Sustainable Concrete Initiative is a collaboration between a wide variety of Danish companies spanning developers, architects, engineers and contractors. The scope of the initiative is to reduce the CO2 emission associated with the use of concrete by 50 % by the year 2030 without compromising safety, quality, comfort or economy. As a partner in the initiative, Optum CE plays an important role in delivering the necessary tools to the industry to enable this transformation. The Danish construction industry already has a focus on sustainability, but with this initiative, it will be possible to further the cause.

Read more about the Sustainable Concrete Initiative (Danish)

New FE software means big savings on materials

The initiative highlights dozens of solutions, each contributing to a reduction in emissions from the concrete industry. One of such solutions is to use new and advanced FE software to optimise our structures and thereby save materials. Optum CE ran a project in collaboration with Niras Consulting Engineers, the Technical University of Denmark (DTU) and the Danish Precast Concrete association (Betonelement-Foreningen) to develop a completely new method of calculating the load bearing capacity of precast concrete structures. The project resulted in a shear wall calculation program (skiveberegningsprogram), which was the basis of the calculation methods used in OPTUM CS. The program makes it possible to save up to 40 % of the reinforcement used in a project without compromising safety and stability.

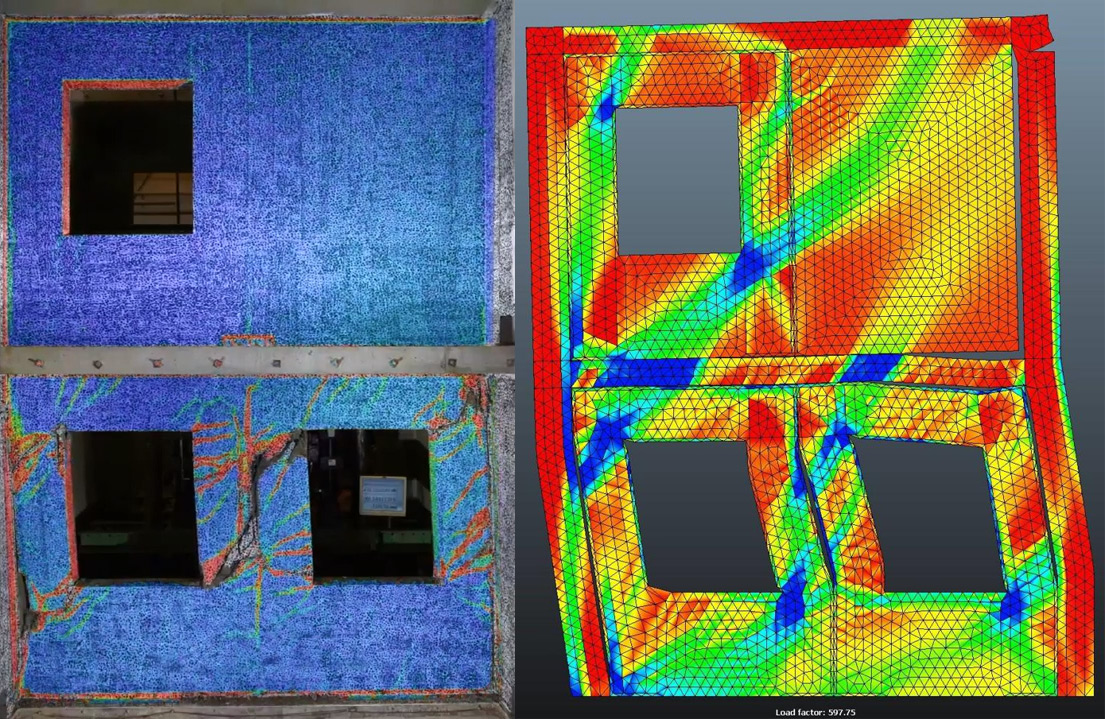

At DTU a series of full scale experiments are being carried out to test the precision of the new calculation method. Photo credit: Mikael Schlosser

The experiments showed that the the calculations matched the reality. Photo credit: Mikael Schlosser

Real life projects and full scale experiments at DTU

The program has already been used by Niras on a large multi-functional commercial building in Ørestad Nord in Copenhagen. The program not only helped the engineers save materials; it also made it possible to design the building with fewer load carrying walls by including the facades in the structural system and thereby increasing the flexibility. With a hotel, restaurant, café, office space and supermarket residing in the building, the increased flexibility is very much required.

Read more about the program and the building here (Danish).

Meanwhile researchers from DTU have conducted a series of experiments to investigate if the assumptions of the new calculation method are present for larger structures. They have constructed several full-scale two-story precast concrete shear walls, which are being destroyed by test machines adding up to 100 tonnes of pressure horizontally. The tests are being conducted in a collaboration with the Danish Concrete Element association (Betonelement-Foreningen). The first test showed results very close to what the program had predicted.

On the left is the actual building with colors added to better illustrate the breaks, on the right the calculations from OPTUM CS.

OPTUM CS will assure a more sustainable future for the concrete industry

Our goal at Optum CE is to enable the engineers to design optimal structures in an easy, reliable and enjoyable manner. Optimal structures mean that the least materials are used in the most efficient way, which of course also leads to lower embedded CO2 in the structure. OPTUM CS is powerful, advanced, and above all user-friendly. Countless hours spend on tedious design tasks and documentation can be a thing of the past. We want to change the world by making sustainability profitable and easy for our clients.

Do you want to learn more about OPTUM CS? Read about CS here or contact us for a personal presentation.